Agitation Devices And Brush Systems

agitation devices

and brush systems

BLOWING BALL

Aluminum and Nylon Rotary, Forward and Reverse.

Aluminum Forward skipper ball for low CFM 6 holes @ 1/16″ dia.

Aluminum Reverse skipper ball for low CFM 6 holes @ 1/16″ dia.

Nylon Forward skipper ball for low CFM 6 holes @ 1/16″ dia.

Reverse skipper ball for low CFM 6 holes @ 1/16″ dia.

Aluminum Reverse rotary skipper ball for low CFM 8 holes @ 1/16″ dia.

Mini Aluminum Forward skipper ball for low CFM 4 holes @ 1/16″ dia.

Mini Aluminum Reverse skipper ball for low CFM 4 holes @ 1/16″ dia.

Plastic Hole Plugs Easy installation into 1″ access Blowing Ball holes in ducts.

WHIP HEAD

The pneumatic cleaning with «WHIP HEAD SYSTEM» action assures a better air duct cleaning job. The economical approach to medium efficiency filters.

WHIP HEAD SYSTEM

The «WHIP HEAD SYSTEM» with High Pressure compressed air powers can do your job, without damaging the ductwork internal insulation. The combination of aggressive hoses movement and compresses air is extremely effective.

The Utra-Flex hoses, can reach, dirt and debris from many angles and do better job.

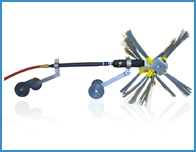

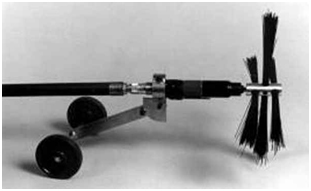

Pneumatic Horizontal Rotary Brush System

![]() Download technical specifications

Download technical specifications

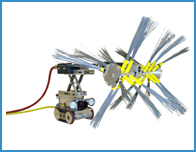

Manual and automated axial brush system

![]() Download technical specifications

Download technical specifications

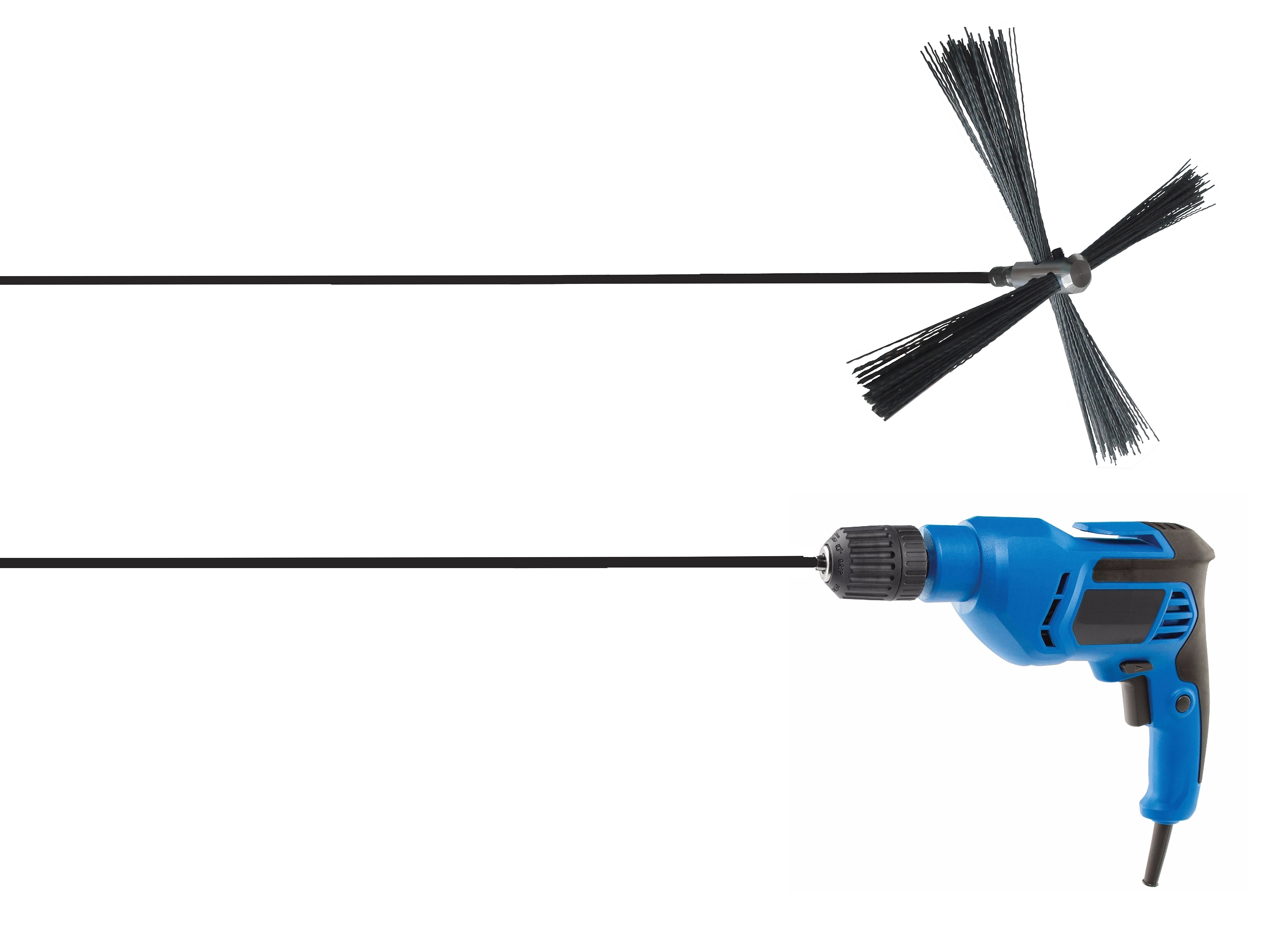

DRILL ACTIVATED SYSTEM

Residential axial rotary brush for drill

13004- Axial brush 12″ with 4 nylon rods of 5/16’’ (0.80 mm) diameter,

adaptor for mandrill and 2 core (for 2 brush size)

Good for 3’’ to 12’’ duct (Drill not included)

Good for dryer vent Small duct opening with 90° elbow.

PYTHON BRUSH

Compare to conventional cable brushing system: no breaking, no kinks, safe, one man operation.

MECHANIZED BRUSH FOR VERTICAL DUCTS

The cleaning of some ventilation ducts requires human insertion. This operation involves risks of cuts, falls, contact with contaminants, thermal discomfort, etc. Often the ducts are too small for safe human insertion or too large, which involves resorting to a complex procedure. It was therefore necessary to find a way to access the confined space and eliminate all these risks at the source. The solution was to use a mechanized brush to clean the vertical ducts. This brush works with a system of pulley and rolling ball on rails in order to facilitate its displacement. With this mechanized brush, human insertion is no longer necessary and the risks are all avoided.